HEXmon Sensors are a wholly UK manufactured and developed solution for 24/7 monitoring of the CNC production work environment.

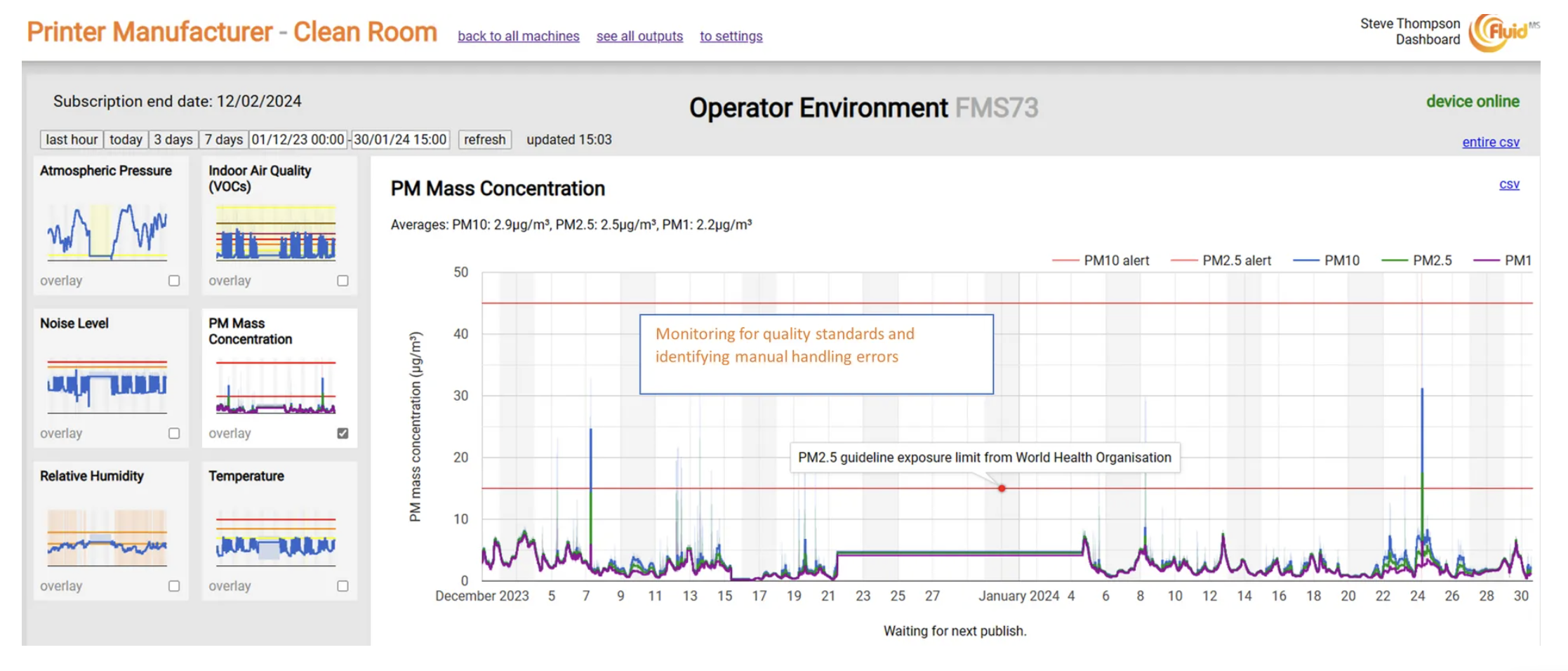

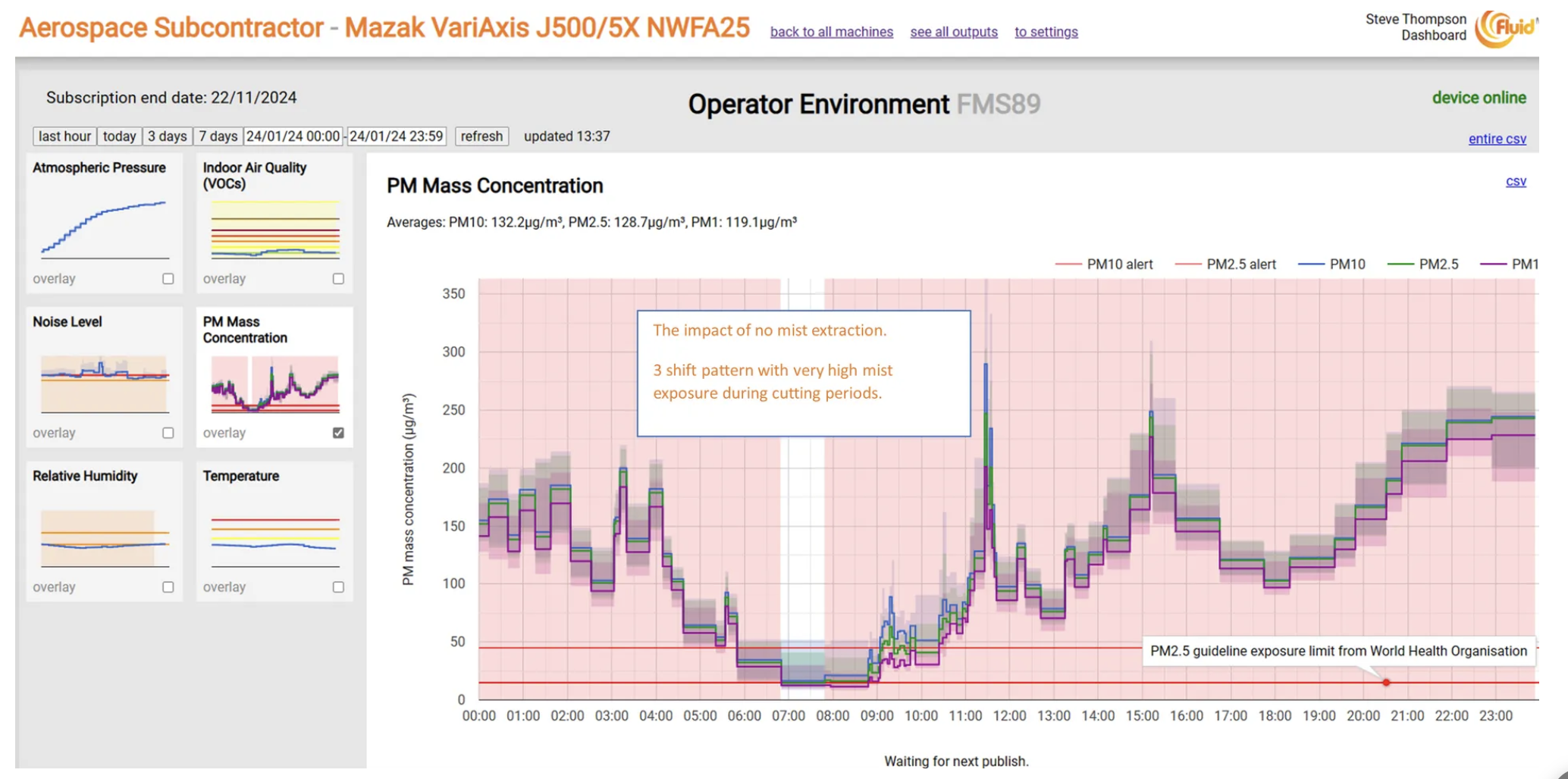

HEXmon users become proactive in identifying emission sources and quickly grasp the effects of mitigation efforts. With 'time series insight', informed decisions can be made and swiftly evaluated to determine the effectiveness of actions taken to reduce emissions.

HEXmon SENSOR is easy to install and use. It provides a complete system for monitoring, notifying, and reporting on indoor air quality in factories, focusing on changes due to emissions from manufacturing. Developed through practical experience and backed by scientific knowledge, it helps identify risks and encourages improvements. It measures dust, fumes, mist, total volatile organic compounds, noise levels, temperature, relative humidity, and atmospheric pressure.

HEXmon helps Health, Safety, Maintenance, and Facilities Teams monitor how emissions affect air quality, allowing quick actions to reduce risks. Its automated monitoring, alerts, and reporting offer a more effective solution than just checking airflow indicators or pressure gauges. Even if airflow indicators seem fine, restricted flow can still harm air quality. HEXmon enhances traditional Occupational Health Exposure monitoring by improving understanding of daily factory air quality, assessing control measures, and observing the effects of process changes.

For a free demonstration on site contact Martin at:-

martins@wire-glide.com

or call on

+44 7557 850370